Awards and Acknowledgments

Notable structural repair industry recognition

QuakeWrap's engineering services, quality materials and industry-leading installations are recognized nationally by notable civil engineering and public utility organizations.

| Year | Award | Description |

|---|---|---|

| 2020 |  Port Repairs to Freighter-Struck Jetty | Read the interview with the Port Engineer responsible for repairing the concrete marine piles that were broken when a freighter collided with the jetty while docking. Using the PileMedic® by QuakeWrap repair system along with FRP rebar for extra strength, the crews were able to make repairs with minimal service interruption to operations. Read More About the Project >> |

| 2020 |  Storm Tunnel Repair Deep Under City | A new application for QuakeWrap’s award winning StifPipe® takes engineers and the FRP Construction team deep underground to repair a 12-foot diameter tunnel running directly beneath the city of Minneapolis. Read the details from the repair project that marks a record as the deepest application of an FRP system for fully structural pipe/tunnel rehabilitation. Read More About the Project >> |

| 2019 |  Steel Sheet Pile Repair Methods Guide | Guide to repairing steel sheet piles used for industrial bulkheads and seawalls is published by the leading journal for the marine construction industry. Detailed, go-to dossier for viable options when repairing corroded steel sheet piles penned by QuakeWrap Senior Engineer Paul A. Thomas, MBA, PE, and Steve Delgado, Marketing Manager. An informative read that includes repairs using FRP (fiber reinforced polymer) and other popular methods. Read More About the Project >> |

| 2019 |  Timber Pile Repair Guide Features PileMedic | PileMedic® by QuakeWrap's extraordinary capability to completely encapsule corroded and damaged timber piles with extremely limited access is on full display in this informative guide published by Pile Buck magazine. PileMedic’s pile repair advantages are the featured photo illustrations in this dossier of all things marine timber piles, penned by the technical writers for Pile Buck. Read More About the Project >> |

| 2018 |  PipeMedic by QuakeWrap helps win Trenchless Project of the Year | QuakeWrap’s large conveyance repair system rehabilitates a large gas pipe in New Jersey and wins Project of the Year recognition from Trenchless Technology magazine. The carbon FRP laminates used in this project are only 0.024 inches thick but are stronger than steel. You can read about this critical repair project here. Read More About the Project >> |

| 2018 |  QuakeWrap Recognized for Exports, Global Economy Contributions | Arizona’s Joint Planning Advisory Council Sun Corridor Export Recognition Program for Economic Development for the Global Economy (EDGE) recognizes the export achievements of QuakeWrap, Inc., for 2017-18. The recognition is for overall export achievements benefiting Pima County as well as the global economy. Read More About the Project >> |

| 2017 |  Kudos for QuakeWrap's In-House Construction Company | QuakeWrap’s in-house installation team, FRP Construction LLC, earns kudos from the Salt Lake City Department of Public Utilities for showing positive attitudes, job site sensitivity and installation diligence during a recent culvert repair job that involved running water, bad weather and other challenges. Read More About the Project >> |

| 2017 |  PileMedic by QuakeWrap Makes the Grade with US Army Engineers | QuakeWrap Inc. was proud to take part in a Joint Capability Technology Demonstrations (JCTD) with the U.S. Transportation Command and U.S. Pacific Command (USPACOM). The demonstrations, in Pearl Harbor, Hawaii, involved U.S. Army and Navy divers implementing the U.S. Army Corp of Engineers PIER program. PIER allows for repair of a damaged structure within days instead of months, or even years, which in turn supports a variety of missions. Pier pilings were repaired with QuakeWrap's PileMedic product to demonstrate the equipment’s use in the field. Read More About the Project >> |

| 2011 |  Trenchless Technology's Project of the Year Award | This coveted award recognizes PipeMedic by QuakeWrap for "CIPP of Leaking High-Pressure Cast Iron Main." PipeMedic laminates were used to bridge a 2-ft gap in a steel pipe -- remotely creating a pipe where there was no steel pipe present! You can read more about this project by clicking here. Read More About the Project >> |

| 2010 |  Award of Merit from International Concrete Repair Institute (ICRI) | This Award was presented to QuakeWrap, Inc. for Emergency Repair of Mile Long Cast in Place Reinforced Concrete Penstock at El Encanto Hydroelectric Power Plant. The pipe was located a mountainous terrains of Costa Rica. This project holds the world's largest single application of FRP in retrofit of a major pipeline. You can read the award announcement here. This article published in several magazines including the ICRI's Concrete Repair Bulletin and ACI's Concrete International. |

| 2010 |  Award of Merit in Structural Engineering from Structural Engineers Association of Arizona (SEAOA) | This Award was presented to QuakeWrap, Inc. for Blast Strengthening of US Army Building Using Fiber Reinforced Polymer (FRP) Technology. An article published in Structure Magazine details the testing program that was done prior to this retrofit. This article published in Public Works Digest describes details of the project. Read More About the Project >> |

| 2009 |  Trenchless Technology Project of the Year Award (Honorable Mention) | This Award was presented to QuakeWrap, Inc. for Emergency Structural Rehabilitation of a Mile-Long 7-ft Diameter Pipeline. The pipe was leaking at thousands of locations. The entire repair of the pipe was completed in a record 15 days. You can read the award announcement here. This article published in AWWA's Opflow, describes some details of the project. To view the article for Trenchless Technology's Project of the Year Award, Click Here. |

| 2008 |  Award of Excellence from International Concrete Repair Institute (ICRI) | QuakeWrap received the 2008 Award of Excellence from the International Concrete Repair Institute (ICRI) for the restoration of Large Diameter Prestressed Concrete Pipelines. Over 700 feet of 120-inch diameter Prestressed Concrete Cylinder Pipe (PCCP) was repaired by application of carbon FRP fabric. To read the full project description in Concrete Repair Bulletin, click here. Read More About the Project >> |

| 2007 |  Award of Merit from International Concrete Repair Institute (ICRI) | QuakeWrap received the 2007 Award of Merit from the International Concrete Repair Institute (ICRI) for the retrofit of the Historic Fox Theater in Tucson, AZ. Read More About the Project >> |

| 2006 |  2006 Award of Excellence from International Concrete Repair Institute(ICRI) | QuakeWrap Inc. is the recipient of the International Concrete Repair Institute (ICRI) 2006 Award of Excellence for its seismic retrofit of the historic McKinley Tower in Anchorage, Alaska. The national award acknowledges QuakeWrap’s creative achievement and innovation in repairing and strengthening the concrete structure. Read the ICRI Article here. Read the article published in Structure Magazine. You may also watch this video by clicking here. Read More About the Project >> |

| 2006 |  2006 Award of Excellence in Structural Engineering | This award was for retrofit of the Historic Fox Theater in Tucson, AZ. Many of the unreinforced masonry walls in this building were retrofitted by bonding glass or carbon FRP fabrics to them. The History Channel made a documentary program about this project that aired on March 26, 2005. You can view that video by clicking here. Read More About the Project >> |

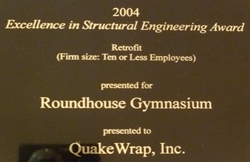

| 2004 |  SEAoA Award of Excellence in Structural Engineering (Retrofit) | QuakeWrap Wet Layup application increases flexural strengthening of glulam beams in a high school gymnasium in Coolidge, Arizona. Locker room beams are retrofitted with carbon strips and carbon fabric for increased live load capacity, allowing installation of bleachers for spectators and earning the Award of Excellence in Structural Engineering from the Structural Engineers of Arizona. You can read more about this retrofit project here. Read More About the Project >> |