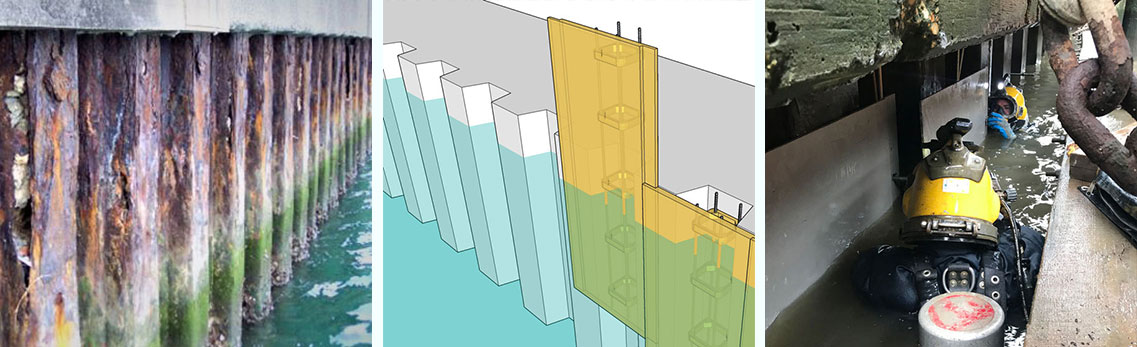

Steel Sheet Piles, Seawalls and Bulkheads

Steel sheet piles, seawalls and bulkheads are commonly used in waterfront projects. The daily tidal changes introduce dry/wet cycles that lead to rapid corrosion of these structures. Most of the damage in sheet piles and seawalls occurs over the splash zone, which is defined by the low and high tide water elevation. The large size of sheet piles, bulkheads and seawalls and the fact that they are partially submerged in water makes their repairs very challenging.

A recent system developed by Prof. Ehsani (U.S. Patent # 10,968,631) offers an economical solution for such repairs. The product is named Sheet Pile Repair (SPiRe®) system and is constructed with lightweight honeycomb or 3D fabric sandwiched between sheets of resin-saturated FRP fabric. These panels can be easily manufactured near the jobsite to match the shape of the steel sheet pile or concrete seawall and bulkhead being repaired. The lightweight panels are secured in front of the repair area using anchor bolts. The annular space between the SPiRe® panels and the seawall or sheet pile is filled with grout or resin. The impervious sheets form a barrier in front of the wall that keep moisture and oxygen away. It is well recognized that oxygen is the fuel to the corrosion process. The impervious SPiRe® shuts off the influx of oxygen and brings the corrosion process to a virtual halt. A variation of the product can be designed to resist the loads as well as protecting the host structure against corrosion damage.

Repair of the underside of decks that are close to the high-water elevation is a challenging task. SPiRe® panels can be custom-made to match the exact geometry of the beams and deck being repaired. These panels can be lifted and secured to the underside of the deck, creating a small annular space that can be filled with concrete or grout. If needed, additional reinforcing bars can be installed or inserted inside the SPiRe® panels before installation. Please watch the video below that demonstrates this technique.

Features & Benefits

Advantages of repairing seawalls and steel sheet piles with SPiRe® include:• SPiRe® works on concrete, steel and timber structures

• Lightweight panels lead to fast and economical repair

• SPiRe® system will not corrode and requires little maintenance

• Impervious FRP system will significantly lower the corrosion rate

• Finished installation can be architecturally coated